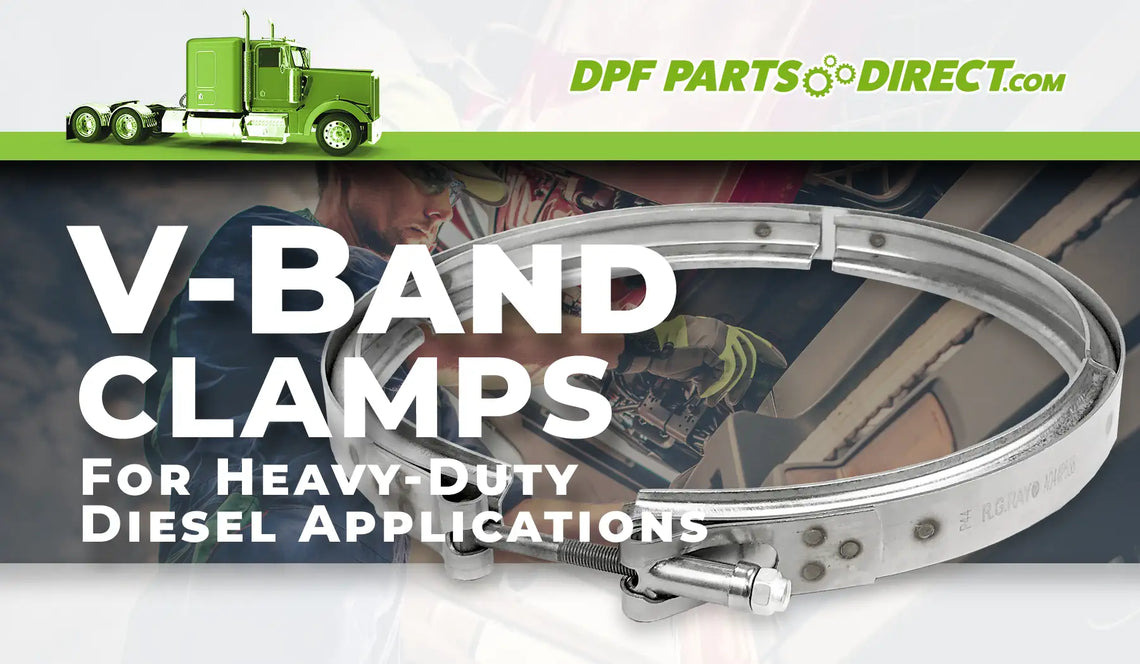

V-band clamps are a small but mighty part of your heavy-duty vehicle. With many applications, v clamps can most often be found in the aftertreatment system. These often-overlooked connectors are essential to the modern heavy-duty diesel engine. There are clear advantages to a v-flange over the traditional bolted flange, especially in high-heat or low-space applications.

These clamps are often more secure over time. The “V” in these clamps is highly engineered for specific uses and applications. They are designed to squeeze a gasket between two pipes being joined together for a leak-free joint. Let’s dig into how v-bands work and why they’re the clear choice for heavy-duty diesel applications.

V-Bands vs Typical Flanges & Gaskets

We’ve come a long way since the days of two-, three-, or four-bolt flange connections. While still used in some light-duty configurations, bolted flanges have the disadvantage of needing gaskets, nuts, bolts, and sometimes glue. All these pieces mean that the mechanic needs room to maneuver tools within the tight confines of the engine.

In addition, typical flange-and-gasket assemblies do not provide equal pressure around the circumference of the fitting and are prone to leaks. There is also an increased risk of a bolt coming loose or corroding, offering more opportunity for leaks and challenges to remove.

V-clamps are the clear winner due to having only one nut to tighten – the rest of the clamp and flange is welded together, providing even pressure around the fitting. V-bands are also lighter and more compact, which is perfect for tight spaces in a diesel application.

Finally, the price of a v-band clamp is comparable to the typical flange-and-gasket assembly. The V-clamp is the gold standard for diesel engines and aftertreatment systems.

How V-Band Fittings Work

V-Bands consist of “V” shaped flanges that are welded to a band. They are generally made of stainless steel. A single nut tightens the band, which evenly distributes pressure around the entire circumference of the fitting. V-clamps don’t need glue or separate nuts and bolts. This means that V-bands are an all-in-one assembly.

The “V” in the name comes from a cross-section view of the inner flange. This “V” shaped piece of metal tightly wedges the two flanged tubes together, creating a seal that gets tighter with torque.

Additionally, V-bands are the perfect choice for a diesel aftertreatment system because they create a tighter seal with heat. Since temperatures around the DPF can reach over 1000ºF, fitted components need to be able to withstand extreme heat. As the metal expands, the v-band will fit even better, keeping emissions down and reducing the chance of leaks. Always ensure that the v-band is rated for high temperatures if used in the aftertreatment system.

How to Use a V-Band Clamp

It is critical to use the correct clamp. Many V-clamps look similar but can be very different. The angle of the “V” and the valley dimensions can make a huge difference in a clamp. Installing a v-clamp is often easier than using typical bolt-flange assemblies. The two pipes being connected need to be flanged, deburred, and cleaned. They then need to be aligned, and the technician needs to ensure they remain aligned during the installation of the clamp.

A gasket is generally used to ensure a tight, leak-free joint. The technician should ensure the v-band is correctly seated oven the flanges, then begin tightening the nut. The nut should be tightened partway, then the technician should ensure the v-clamp is still seated correctly over the flanges. Several light taps with a hammer around the circumference will ensure a good fit. Each V-band will need a certain amount of torque, so check with the manufacturer to make sure the v-band is at the proper torque value. Do not over-torque or use air-powered tools.

While V-bands can sometimes be reused, they are subject to high heat, road vibration, and pressure. So it is recommended that in emission exhaust systems, the V-band clamps should always be replaced whenever a component is serviced. This will allow the installer to be sure of a good, tight, leak-free connection. For uses like securing the DPF components, it is essential to use a new v-band at each servicing interval.

Best Applications for V-Band Clamps

V clamps are ideal for use in tight areas due to their compact size. They’re also great for reducing weight because they are lighter than traditional bolt flanges. They make assembling and disassembling quicker.

All these make v-bands ideal for serviceable parts on a heavy-duty diesel engine. They’re an especially great choice for the aftertreatment system, for these reasons and the fact that high heat helps them create a better seal. Because of this, many heavy-duty manufacturers have transitioned to v-clamps.

Where to Buy Affordable & High-Quality V-Clamps

If you’re looking for affordable, high-quality V-clamps in stock, you can find them at DPFPartsDirect.com. We carry a full line of direct-fit OEM replacement v-clamps for many popular makes and applications. These are precisely designed exhaust v-band flanges, v-band turbo flanges, as well as stainless steel v-clamps and other materials.

Contact Us today if you would like more info! Our experts are available Monday through Friday to help you decide which v-band assembly is right for your vehicle. We look forward to helping you find the V-band connector you need.

Comments 0