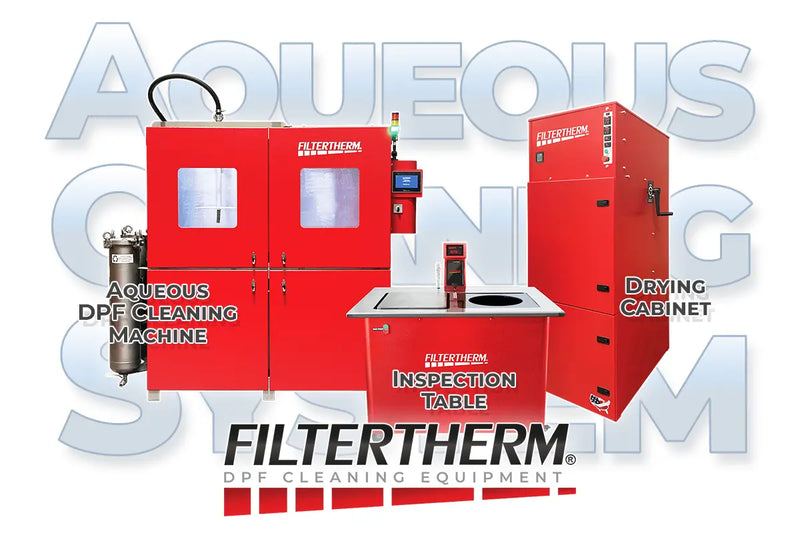

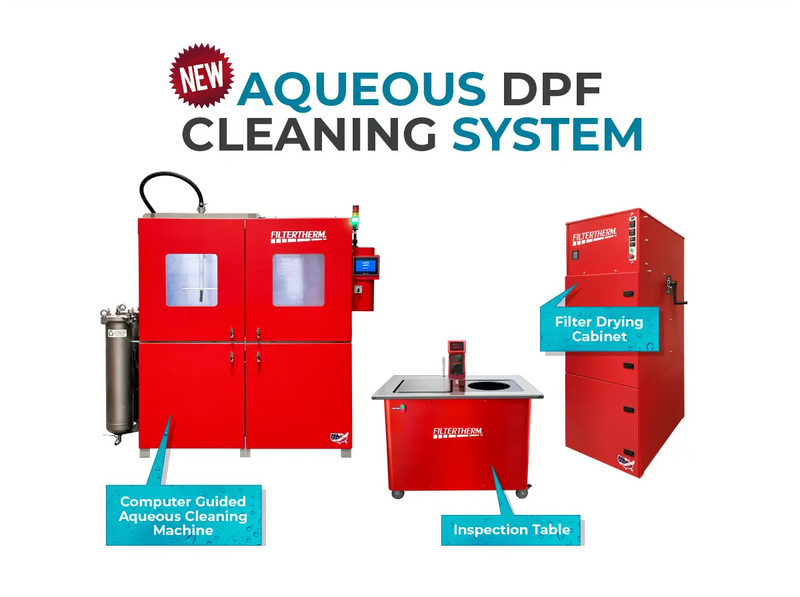

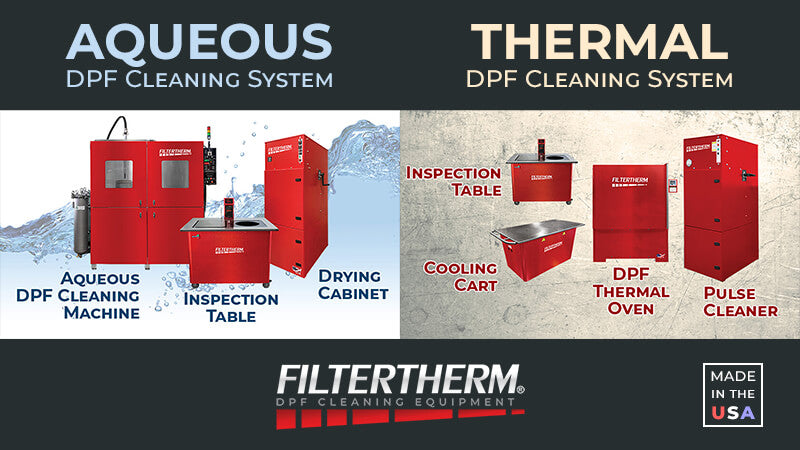

Filtertherm® Aqueous DPF Cleaning Package

The Filtertherm® Aqueous DPF Cleaning Package takes DPFs from dirty to clean in under 2 hours with no baking required!

The package includes:

- Filtertherm® Aqueous DPF Cleaning Machine: FTM 1100

- Filtertherm® Drying Cabinet: FTM 2000

- Filtertherm® Inspection Table: FTM 8003

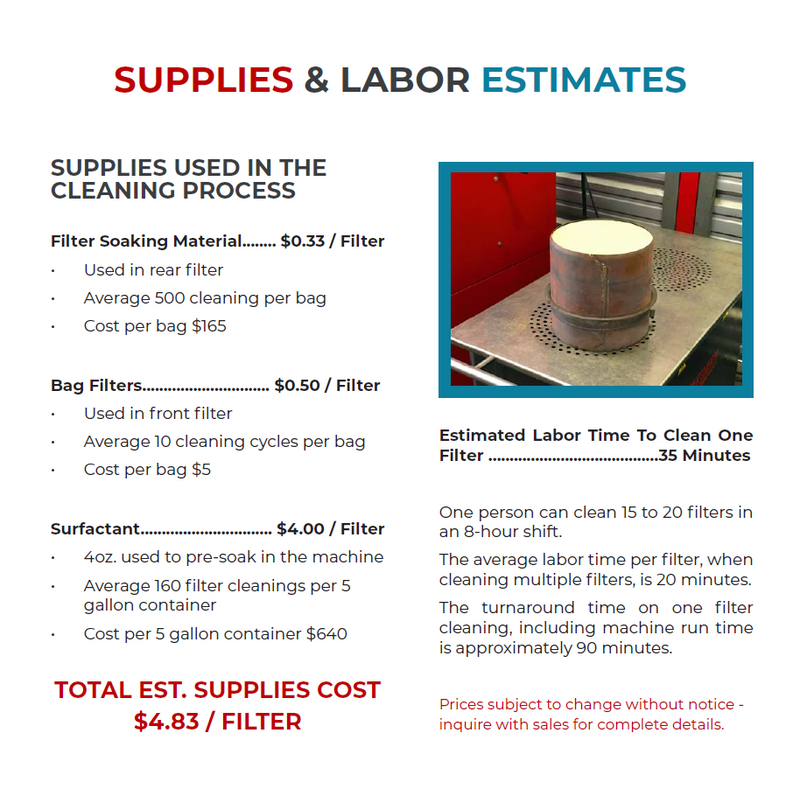

- The Aqueous DPF Cleaning Machine comes with 1-gallon Surfactant Premix, 10 Bag Filters, 5lbs. Filter Soaking Material - sufficient to clean 30-50 filters.

Filtertherm® Remote Dust Collection Kit

The FILTERTHERM® Remote Dust Collection Kit FTM 8004 is made up of a mini portable cyclone dust collector and a mini DPF table. Features include:

- Industrial 115V U.S. made fan motor provides ample CFM for any single tool with a 4"-6" dust port.

- High efficiency cyclone (over 99% separation) with smooth, compound molded surface.

- 22 gallon mobile, drop-down, dust bin with liner bag holder and fill level viewing window.

- 3rd party tested, hospital-grade HEPA filtration with non-stick membrane and vacuum hose port for easy cleaning.

- Highly mobile and compact footprint ideal for smaller workshops with limited space.

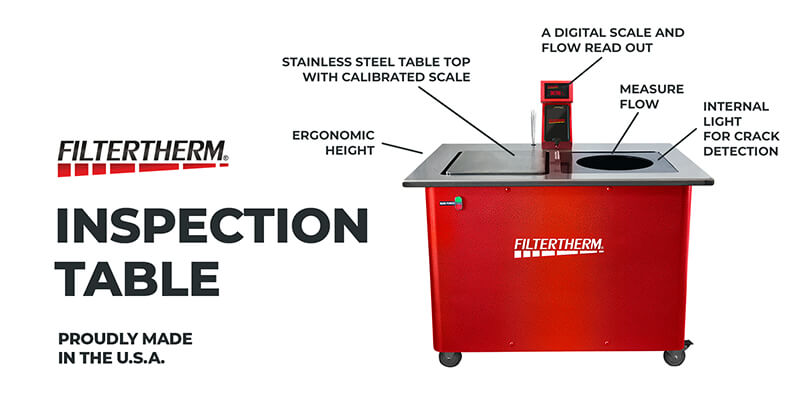

Filtertherm® Inspection Table

Designed for DPF cleaning, our FILTERTHERM® Inspection Table is the perfect compliment to the FILTERTHERM® regeneration oven. It comes complete with a digital scale. It not only measures DPF flow but also weighs the filter to let you know how many grams of ash / soot was recovered during the cleaning cycle. This unit requires 120 volt, single phase 19 amp service.

Filtertherm® DPF Cool Down Cart

The DPF cleaning process can quickly become time consuming, with the typical time between pulling, cleaning and reinstalling a clean filter is about 24 hours. The Filtertherm® DPF Cleaning System is specifically designed to streamline this process and reduce valuable downtime. Hot filters increase downtime waiting for them to cool; thus the Filtertherm® DPF Cool DownCart was born. Our cooling cart decreases the cooling time by 2 - 4 hours (depending on environment), allowing your shop to decrease downtime and increase productivity.

The Filtertherm® DPF Cool Down Cart is designed to cool hot filters before and after the cleaning process, is simple to operate and is an efficient compliment to the rest of the Filtertherm® DPF Cleaning System.

Filtertherm® Thermal DPF Oven

This DPF Thermal Oven is specifically designed for DPF cleaning as opposed to other ovens that are based on kilns. It is made with Cool-Touch Technology, which makes the outside of the unit safe to touch while baking. The design is packaged for shop applications and can accommodate cleaning multiple DPFs at once.

Also, it’s built to UL specifications and proudly made in the United States.

- Industry's first "Smart Touchscreen" Pre-Programmed for all DPF substrates

- Built for the Heavy Duty diesel market

- Pre-programmed for all DPF substrates

- Auto Selects the correct temperature profile for single or multiple filters

- Auto Shutoff for over-temperature conditions

- Stainless Steel grate included

- Powder-coated for durability

Filtertherm® Pulse Cleaner

The Filtertherm® Pulse Cleaner is an enclosed automated unit utilizing high volume low-pressure air for DPF cleaning in 15 minutes or less.

The backpressure gauge allows for easy data recording to ensure complete cleaning and there is a high-temperature lockout to prevent damage to persons and property.