DPF Weld Bungs might be small, but they are an important element in an aftertreatment system. Sometimes they get damaged or break during routine maintenance. (To prevent this, see the Pro-Tip below).

Figuring out the right bung can be a challenge. We're here to help.

In this DPF Weld Bung guide, we lay out 2 ways to determine the right weld bung for your repair. The quick way, or the in-depth way – you decide.

The Quick Way

First, you can try to determine the OEM part number of the sensor, DPF or DOC for the weld bung that is being replaced. Then call us with that info. In most cases, we can find the correct bung based on that.

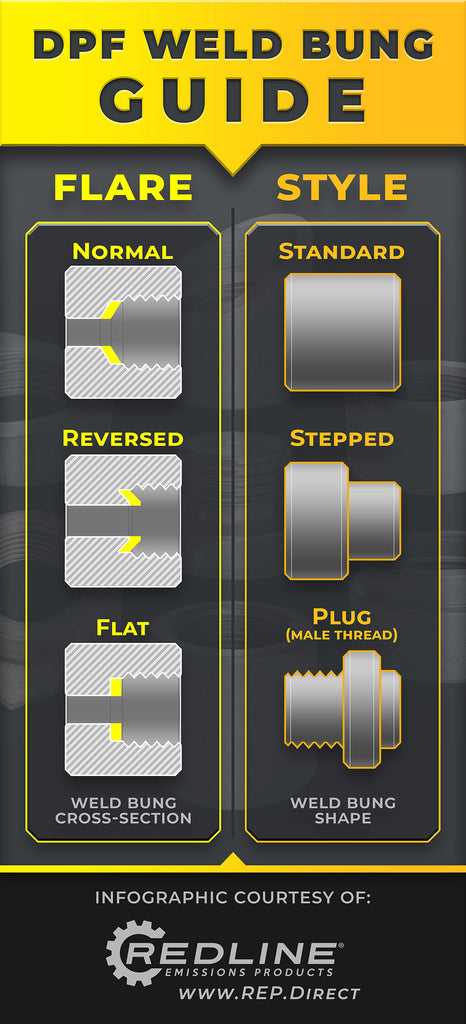

Second, If you know the Flare type (Normal, Reversed, or Flat), Style (Bung shape: Standard, Stepped, or Plug/male thread), plus the size and tread pitch for the bung, visit our Bungs page to find the right bung using the TAGS functionality in the left side bar.

We have created a DPF Weld Bung Guide chart that can help you visually identify the DPF weld bung you need. See below.

Need to double-check or still not sure? It is worth a quick phone call, email, or online chat with one of our US-based parts experts who can help clear up any questions.

Pro-Tip: To prevent the dreaded bung breakage, always apply anti-seize when installing a sensor.

Because DOCs and DPFs are often exposed to harsh environments, sensors can become galled in their "housing", aka the DPF Weld Bung, making them difficult to remove. This can cause damage to the existing weld bung or the sensor and some skinned knuckles. Always make sure to apply anti-seize to your weld bung when installing a sensor to prevent galling and headaches down the road.

Note: All Redline Emissions Products (REP) sensors include anti-seize for this very reason.

The In-Depth Way

Identify the Application:

- Sensor Type: Different sensors require different bung sizes and thread patterns. Common sensors in diesel exhaust systems include temperature, pressure, oxygen (O2), and nitrogen oxides (NOx) sensors. Each has specific bung requirements.

- Location: Bungs are installed at various points in the exhaust system, depending on the sensor's function. Knowing the precise location will help narrow down compatible bung options.

Measure the Existing Bung (if applicable):

- Thread Size and Pitch: Use a thread gauge to measure the diameter and thread pitch of the existing bung. Common thread sizes range from M10 to M22, with pitches of 1.0, 1.25, and 1.5.

- Flare and Style: Identify these 2 aspects on the existing bung to ensure proper compatibility with the sensor.

- Look at the type of FLARE: Normal, Flat, or Reversed.

- The other main characteristic is STYLE: Standard, Stepped, or Plug (Male Thread).

- There are also other dimensions provided such as OD, ID, & Height, that can help narrow down the search.

Seek Expert Advice:

- Diesel Mechanic: If you're unsure about any aspect of bung selection, consult a qualified diesel mechanic. They have the expertise to identify the correct bung based on your vehicle and specific needs.

- Parts Suppliers: Reputable auto parts stores and online stores such as ours, specializing in diesel emissions systems, can also offer valuable guidance in choosing the right weld bung.

Additional Considerations:

- Material: Choose bungs made from high-quality stainless steel (e.g., T304) for optimal durability and corrosion resistance in the harsh exhaust environment.

- Brand Reputation: Select bungs from reputable brands (such as Redline Emissions Products) known for their quality and compatibility with emissions systems.

- Double-check: Before installing/welding, always double-check the bung's compatibility with the sensor and ensure all measurements and thread patterns align properly.

By following these steps and seeking expert advice, you can get the right DPF weld bung for the job.

Comments 0